FPW 550

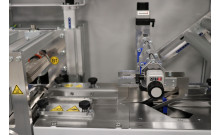

Horizontal flow pack wrapper with high-mounted reel and rotary sealing bars.

Sealing length: 150mm.

Speed: 100 to 200 products per minute.

En savoir plusDescription

Discover the FPW Series: Next-Generation Flow Pack Packaging Machines

The FPW series offers a range of state-of-the-art flow pack packaging machines designed to provide an efficient, precise, and flexible solution. Ideal for packaging small or irregularly shaped products, the FPW series ensures optimal adaptability to various production configurations. Whether your products arrive in bulk (single-dose) or grouped (multipack), these FW models perfectly meet efficiency requirements while ensuring great flexibility in use.

Advantages and Cutting-Edge Technology

Thanks to a rotary bar sealing system, the jaws ensure sealing and cutting to produce neat, precise, and airtight packages, guaranteeing optimal product preservation. Their design incorporates advanced technical features that enable fast and efficient packaging, suited to demanding industrial environments.

Key Technical Features

- Flow Pack Design with Upper Film Roll: Designed to facilitate film insertion with a sturdy and ergonomic structure.

- Rotary Bar Transverse Sealing: A 250 mm wide sealing bar system ensures reliable and secure packaging.

- 1500 mm Feeding Conveyor with Adjustable Guides: This long conveyor enables continuous feeding and adapts to different product formats with easily adjustable guides.

- Feeding System with Adjustable Guides and Removable Paddles: Adjustable guides and removable paddles simplify the product loading process.

- Longitudinal Sealing with Three Pairs of Drive Wheels: An innovative technology with three pairs of wheels for precise sealing. The first pair pulls the film, the second performs the sealing, and the third folds the film for optimal finishing.

- Pneumatic Opening of Longitudinal Sealing Wheels: Allows for easy operation management and enhanced safety.

- Motorized Upper Film Holder with Pneumatic Expanding Shaft: A motorized film holder system for smooth and quick film changes, improving productivity and reducing downtime.

- Dynamic Film Former: Adaptable with a digital position display, allowing for instant adjustments as needed.

- Memorizable Height Adjustment for the Sealing Bar (Center Seal): The sealing bar height is motor-adjustable and can be memorized, enabling quick retrieval of ideal configurations for each product.

- Motorized Exit Conveyor: Height-adjustable for optimal compatibility with different types of products.

Integrated Control System and Advanced Functions

The FW series features a sophisticated and intuitive electronic control system, facilitating the regulation of each step of the packaging process:

- Film Tension Control: An electronic system maintains optimal tension for wrinkle-free and distortion-free packaging.

- Three-Point Temperature Control: Precise and independent temperature control for each sealing section—longitudinal sealing, upper transverse sealing, and lower transverse sealing—ensuring optimal sealing and consistent quality.

- Production Statistics and Monitoring: Instant production indicators, piece counter, and machine efficiency tracking for enhanced performance monitoring.

- Programming and Memory Storage: Capability to store up to 50 different work cycles, simplifying production changes.

- Safety Features: Emergency stop button, end-of-film sensor, and "no product - no bag" function for secure operation.

A Solution Compliant with Standards and Energy-Efficient

Compliant with CE regulations, these machines stand out for their low energy consumption, enhanced safety, and industrial efficiency.

Enter a new dimension of productivity and performance, ensuring high-quality packaging and flexible use perfectly suited to modern industrial needs.

Product dimensions and speed are provided as an indication and depend on product size, package format, and film type used.

- Speed: 100 products per minute with a single transverse sealing bar.

- Speed: 200 products per minute with two transverse sealing bars.

- Reference

- FPW 550

- Sealing length

- 250 mm

- Supply

- 3PH+PE / 3PH+N+PE

50/60 Hz

220 - 240 V / 380 - 415 V

Pneumatic

Électric - Pace maxi.

- 100 ppm / 200 ppm

- Pressure

- 6 bar

- Consumption

- 4800 W

- Maximum Product Height*

- 120 mm

- Maximum Roll Diameter

- 350 mm

- Net weight

- 760 kg

- Dimensions machine

- 4085 x 1375 x 2155 - 2255 mm