IMPACK HYBRID

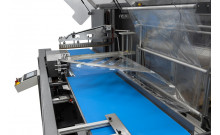

The IMPACK HYBRID Servo continuous wrapper is an automatic horizontal film wrapping machine with continuous longitudinal sealing and product transfer management via 3 belts.

En savoir plusDescription

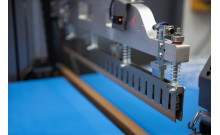

This machine can be paired with a shrink tunnel and is designed for high-speed production. It operates with center-folded film, and its cycle is fully automatic. The products to be packaged are placed manually or automatically on a feed belt, and a horizontal sensor automatically detects the length of the products. This allows for switching between products of different lengths without adjustments. An adjustable former allows the film's positioning to be adjusted according to the product's size. The film is sealed around the product on three sides using a continuous seal-cut system with a heated knife and a fixed transverse seal-cut jaw.

- Centering of longitudinal and transverse seals

- Adjustable pressure for cutting and sealing

- Sealing temperature controlled by PID

- Sealing blade for various packaging materials

- Product position detection under the sealing bar by sensor

- Memorizable programs with alphanumeric identification

- Compact and aesthetically pleasing design

- Vertical sealing with servomotor, electric movement

- Automatic detection of product length

- Custom design and reinforced mechanical properties for high-quality products

- Color touchscreen operator panel

- Automatic film feed with tension control

- Automatic winder with tension adjustment and detection of film break or end

- Adjustable speed conveyor

- ISO 9001 manufacturing

- ISO-standard mechanical, electrical, and pneumatic components (see list)

- CE certifications, compliant with the latest CE directives

- Sealing length

- 730 mm

- Conveyor width

- 600 mm

- Voltage

- 400 V 3PH + T + N

- Weight Gross

- 1350 kg

- Maximum Product Width*

- 600 mm

- Maximum Product Height*

- 400 mm

- Maximum Film Width

- 1000 mm

- Machine dimensions

- 1850 x 3300 x h 1800 mm