WFPS

These machines are automatic cartoners that provide solutions for packaging your products in various forms. Multiple versions are available, depending on your production speed, application type, and product entry method.

En savoir plusDescription

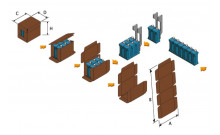

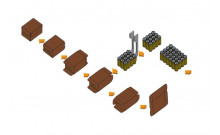

The WFPS series of wrap-around automatic cartoners is designed to meet demanding production and quality standards. This range offers flexible solutions for packaging your products into trays, open boxes, closed boxes, ready-to-sell packaging, or display boxes.

With its compact design, the space required for installation is significantly reduced. Despite its small footprint, the machine integrates cutting-edge technology, ensuring high speeds of up to 25 packs per minute, depending on product dimensions and materials used.

Boasting great adaptability to materials, WFPS machines are compatible with three types of cardboard: micro-corrugated, corrugated, and kraft. This versatility allows them to meet the diverse needs of different sectors, delivering precise and robust packaging while optimizing production cycles.

Wide Range of Industrial Applications

These cartoners cater to a variety of markets:

- Beverages: milk, water, beers, wines, and other drinks.

- Food products: canned vegetables, sauces, edible oils, etc.

- Hygiene and care products: shampoos, detergents, cosmetics.

- Specialized industries: aerosols, pharmaceuticals, lubricating oils, logistics, and custom packaging.

Key Benefits

- Performance: optimized speeds for fast production cycles.

- Flexibility: easy adaptation to various formats and materials.

- Efficiency: ideal for meeting the growing demands of modern supply chains.

- Reliability: robust and durable design for consistent performance.

The WFPS series is the ideal solution for manufacturers looking to streamline their packaging operations while ensuring high-quality, market-ready packages.

|

Reference |

WFPS 150R |

WFPS 150Z |

WFPS 280R |

WFPS 350R |

WFPS 350Z |

WFPS 600R |

WFPS 600K |

|

Entry model of products |

In line |

90° |

In line |

In line |

à 90° |

In line |

In line |

|

Minimum height of products |

75 mm |

75 mm |

75 mm |

75 mm |

75 mm |

75 mm |

- |

|

Maximum height of products |

350 mm |

350 mm |

350 mm |

350 mm |

350 mm |

350 mm |

- |

|

Height of working board |

960 - 1105 mm |

960 - 1105 mm |

960 - 1105 mm |

960 - 1105 mm |

960 - 1105 mm |

960 - 1105 mm |

960 - 1105 mm |

|

Power sypply (electric) |

3PH + PE |

3PH + PE |

3PH + PE |

3PH + PE |

3PH + PE |

3PH + PE |

3PH + PE |

|

Voltage |

220 - 240 V |

220 - 240 V |

220 - 240 V |

220 - 240 V |

220 - 240 V |

220 - 240 V |

220 - 240 V |

|

Consumption |

9700 W |

10400 W |

9900 W |

10000 W |

10600 W |

11100 W |

12400 W |

|

Power supply (pneumatic) |

Requierd air : 17 L/P |

Requierd air : 17 L/P |

Requierd air : 17 L/P |

Requierd air : 17 L/P |

Requierd air : 17 L/P |

Requierd air : 17 L/P |

Requierd air : 17 L/P |

|

Pressure |

6 bar |

6 bar |

6 bar |

6 bar |

6 bar |

6 bar |

6 bar |

|

Pace |

20 p/min |

25 p/min |

20 p/min |

25 p/min |

25 p/min |

25 p/min |

25 p/min |

|

Weight Net |

1855 Kg |

1960 Kg |

1875 Kg |

2060 Kg |

2160 Kg |

2115 Kg |

- |

|

Machine size (cm) |

479 x 241 x 219-233 |

479 x 355 x 219-233 |

479 x 241 x 219-233 |

559 x 241 x 219-233 |

479 x 355 x 219-233 |

559 x 241 x 219-233 |

559 x 241 x 219-233 |