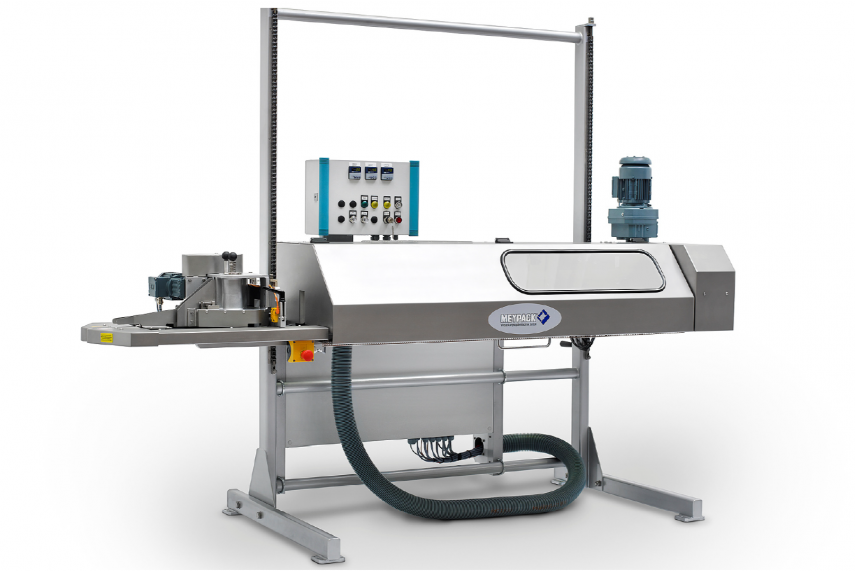

Meypack Série CBS

Continuous sealer for closing bags made of thermoplastic film and woven polypropylene with an internal pouch.

En savoir plusDescription

MEYPACK offers a wide range of continuous sealing machines based on the band welding principle of the Doboy system, allowing for airtight and hermetic closure of plastic bags. The perfectly uniform seal, created with heated bars and continuous belts under pressure, ensures high-quality sealing. Models equipped with water-cooling bars cool the seals by holding them under pressure between the belts, resulting in very smooth seals. In contrast, models with air cooling produce wavy seals, as they do not maintain pressure during cooling. Additional equipment enables the machines to adapt to specific and challenging applications, such as packaging dusty products.

Operating Principle:

The sealing machines in the CBS series operate continuously based on the band welding principle. In the sealing area, steel belts coated with a PTFE layer guide the bag through the heating section. This system allows for optimal heat transfer and prevents the film from direct contact with the heat source. The heating section consists of heating bars, the number of which depends on the model and the required speed. The temperature of the heating bars is precisely adjustable, enabling consistent welding suited to the bag material. After welding, the seals are cooled by air or water-cooled bars. Toothed belts running directly beneath the steel belts ensure the top of the bag remains in a perfect (folded and flat) position throughout the machine. Additionally, the bags are supported by a conveyor (optional equipment).

The CBS-D95 series machines, featuring high-performance sewing heads, are used to seal woven polypropylene bags. These machines weld the internal pouches and sew all layers of the bags.

Advantages:

- Robust construction designed for multi-shift operation.

- High heat utilization efficiency due to spring-mounted heating bars.

- Easy to use and maintain, thanks to excellent accessibility.

- Quick changes of bag dimensions.

- Bags can be introduced automatically or manually.

- Compatible with all known packaging lines and formers.

| Reference | CBS-A 400 SH | CBS-W 400 | CBS-A 600 | CBS-W 600 | CBS-A 1000 | CBS-W 1000 | CBS-D95 600 | CBS-D95 1000 |

| Heating section | 2 x 200 mm | 2 x 200 mm | 3 x 200 mm | 3 x 200 mm | 5 x 200 mm | 5 x 200 mm | 5 x 200 mm | 5 x 200 mm |

| Speed | 14 m/min | 14 m/min | 22 m/min | 22 m/min | 24 m/min | 22 m/min | 13,5 m/min | 21 m/min |

| Heating power | 1800 W | 1800 W | 2700 W | 2700 W | 4500 W | 4500 W | 4300 W | 3600 W |

| Length | 2300 mm | 2950 mm | 2950 mm | 2700 mm | 4150 mm | 3350 mm | 4300 mm | 3600 mm |

| Width | 1120 mm | 1120 mm | 1120 mm | 1120 mm | 1120 mm | 1120 mm | 1120 mm | 1120 mm |

| Height | 1950 mm | 1950 mm | 1950 mm | 1950 mm | 1950 mm | 1950 mm | 2600 mm | 2600 mm |

*Other models available upon request, as the CBS series is the most modular.