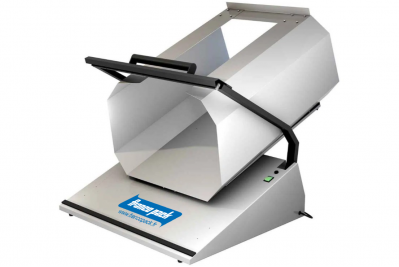

Manual bagging machine operating from a polyethylene sleeve placed over a chute. Sealing length: 400 mm.

Pandyno

L’ensacheuse et soudeuse Pandyno assure l’ensachage et la fermeture du sachet à partir d’une gaine préalablement manchonnée sur une goulotte. La machine est équipée d’une barre de soudure de largeur 5 mm. Les temps de soudure et de refroidissement sont réglables en fonction de l'épaisseur du film grâce à une minuterie. A chaque cycle, un fil métallique tendu sur le caoutchouc du bras mobile vient couper la soudure en deux pour fermer le sac et faire le fond du sac suivant. La coupe est toujours franche et il n’est pas possible de faire des chapelets de sacs. Le fonctionnement est simple : les produits à conditionner sont introduits en haut de la goulotte et descendent de leur propre poids en entraînant dans leur chute le fond de la gaine (préalablement soudé), jusqu’à la butée de réception qui est réglée en fonction de la hauteur du sac à obtenir. Il suffit d’appuyer de la main sur le bras mobile pour déclencher le cycle.

There are 6 products.

Manual bagging machine operating from a polyethylene sleeve placed over a chute. Sealing length: 400 mm.

Manual bagging machine operating from a polyethylene sleeve placed over a chute. Sealing length: 400 mm.

Manual bagging machine operating from a polyethylene sleeve placed over a chute. Sealing length: 400 mm.

Manual bagging machine operating from a polyethylene sleeve placed over a chute. Sealing length: 400 mm.

Manual bagging machine operating from a polyethylene sleeve placed over a chute. Sealing length: 400 mm.